Masterbatch Filing Equipment Tse-75b in Plastic Twin Screw Extruder

1.The Technical DataÂ

| Model | Diameter | L/D | Screw Speed | Screw Torque | Motor Power | Capacity | Weight | ||||

| TSE-20 | 22mm | 32-44 | 600r/min | 43N.m | 5.5kw | 0.5-10kg/h | 1000kg | ||||

| TSE-30B | 31mm | 32-48 | 600r/min | 119N.m | 15kw | 5-40kg/h | 1500kg | ||||

| TSE-35B | 35.6mm | 32-52 | 600r/min | 119N.m | 15-22kw | 20-60kg/h | 1500kg | ||||

| TSE-40B | 41mm | 32-52 | 600r/min | 239N.m | 30kw | 90-150kg/h | 3000kg | ||||

| TSE-50B | 50.5mm | 32-52 | 500r/min | 430N.m | 45-55kw | 135-270kg/h | 3000kg | ||||

| TSE-65B | 62.4mm | 32-64 | 600r/min | 716N.m | 90kw | 200-300kg/h | 4000kg | ||||

| TSE-75B | 71mm | 32-64 | 600r/min | 1050N.m | 132kw | 350-550kg/h | 4000kg | ||||

| TSE-75D | 71mm | 32-64 | 600r/min | 1990N.m | 200-250kw | 500-1000kg/h | 4000kg | ||||

| TSE-95B | 93mm | 32-64 | 600r/min | 2506N.m | 315kw | 800-1200kg/h | 4000kg | ||||

2.Applicable Scope:

Used for continuous automatic quantitative packing of such as plastic granules, wheat, corn, rice, malt, oil plants, seed, chemical fertilizer, feedstock , bean residue and so on.

Â

3.Functions and Features :

1.Integrate feeding material, weighting, bag clipping, bag packing, conveying and sealing.

2.Automatic pack reduction and automatic calibration during the weighing each time.

3.Have functions such as long-range controlling and trouble diagnosing, repairing , ultra difference alarms and so on.

4.Adopt gravity feeding method internally inside the package to ensure high metering accuracy and fast packing speed.

5.24-bit fast A/D converter and intelligent digital filtering technology, strong anti-interference, fast and stable.

6.Weight meter adopts aluminum alloy enclosure, with high anti-interference performance and simple operation.

7.Double CPU construction, with power down data protection inside the unit.

8.Full enclosure design, negative pressure operation inside the unit, without dust escape, with clean environment.

1. Electric Control System

Frame structure control cabinet

Imported electrical elements

Imported temperature control system

Imported driving system

Interlock and multi-protection

Adopting imported PLC (OMRON or SIMES ) to achieve optimized process control.Stronger function, steady performance and much higher accuracy.

It can be also accomplished full-set link-lock protection,trouble safeguard, fault alarm cluing and so on

Operation interface on touching screen is visual and marked, which is brief and easy to use.

2.The Gearbox

New-style project of parallel three-axises driving makes the convey axis,convey chain,decelerate and the torque assignment get together,which keeo it compact,and the key bearings are imported.

The select material of drive components is dainty. Including super intension alloy cementiteing steel,cementiting and quenching ,gear grinding technics ,strengthening of tooth face.So they can ensure high torque,high precision and low noise.

Soakage and coerce lubrication integrate smoothly.When the hydraulic circuit is over pressed, it alarms

3.Mixing and Feeding System

4.The Screw Barrel

Euro-style rectangle barrel,reflux refrigeration is optimized and disposed,which makes temperature difference in C areas smaller

According to the material and special techinics demands,the material of cylinder can use high quality nitrided steel,corrosion proof or antifriction with corresponding process

The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat- treament

5.Pelletizer

4.Ce and ISO 9001 Certificates

Â

5.Shipment:

Wooden cases or customized

6.Service System

Before-sale:

*Introduce products in detail

*Recommend suitable solution

*Offer test

During Manufacturing:

*Provide layout and engineering conditions

*Offer screw plan and related documents

*Inform the project processing status

*Insure the product designed in accordance with technical document

After-sale:

*Provide installation, commissioning and training

*Offer spare parts

*Provide necessary technical support and update information

FAQ

1. Q: How about Haisi?

R: Nanjing Haisi Extrusion Equipment Co., Ltd. is a High-Tech company. Our firm is composed of a strong team that has substantial experience in R&D, manufacturing, technique, and service, and has specialized in the extruder industry for ten years, making us one of the leading manufacturers of screw barrels in China.

2. Q: What's Haisi capacity?

R: Our company strictly follows CE and ISO9001 quality certification systems. We have over 200 models of extruders and spare parts available.

3. Q: What's the delivery time?

R: For regular sizes, we have finished stock and semi-finished stock. Customized orders typically take up to two weeks, but usually 3-4 weeks.

4. Q: Where is Haisi factory and how to reach there?

R: Located in Lishui, Nanjing, Jiangsu Province. If you want to visit, we can pick you up at the airport or train station.

5. Q: How to contact with us?

R: Please reply directly if you have any questions.

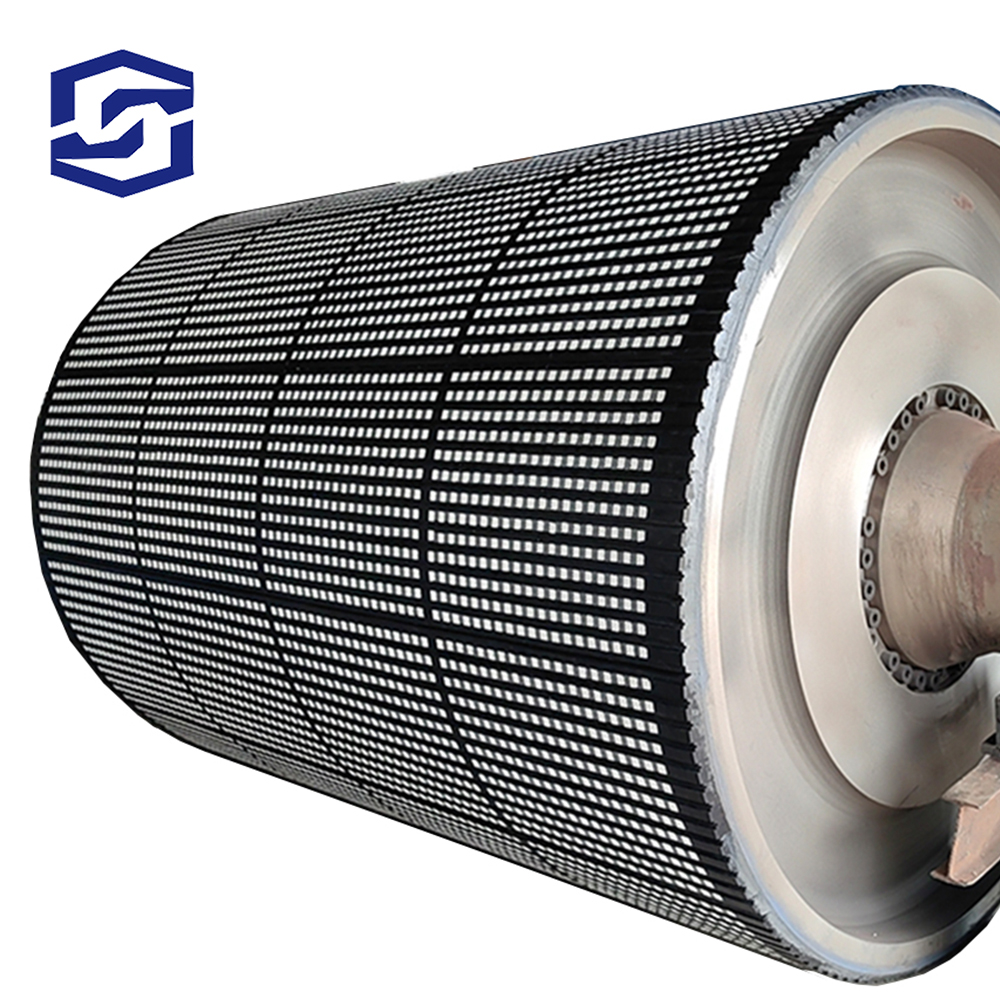

Roller Covered Ceramic Rubber Sheet

ceramic rubber plate,belt conveyor roller covering ceramic rubber sheet,Roller covered ceramic rubber sheet,Wear resistant ceramic rubber sheet,ceramic rubber lagging

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com