If your Toyota is making strange or unusual noises, don’t ignore them. These sounds are often your car’s way of signaling that something isn’t working properly. Paying attention to these clues can help you identify the issue early and prevent more serious problems down the road. Use this guide to help you troubleshoot the most common noises you might hear from your Toyota.

- Bang: A sudden, loud noise like a gunshot could mean your engine is backfiring. This might be due to a rich air/fuel mixture or incorrect timing. Check your fuel system and ignition timing if you hear this sound.

- Boom: A deep, hollow sound when driving may be caused by a misaligned driveshaft or worn universal joints. This can create vibrations that feel like they’re coming up through the floorboard.

- Buzz: A buzzing noise inside the cabin could be from loose trim pieces or dashboard components. Inspect the interior for anything that might be vibrating or rattling.

- Chirp: A high-pitched chirping sound might come from a worn belt or idler pulley. Check the condition of your serpentine belt and related components.

- Clank: A heavy clanking noise during gear shifts could indicate a problem with the rear pinion bearing or other internal transmission parts.

- Click: A clicking sound while turning might point to a faulty outer CV joint. If it happens under the hood, check the engine for issues like dirty oil, a stuck lifter, or a bent pushrod.

- Clunk: A heavy thud when driving over bumps may signal worn suspension bushings or strut mounts. Inspect those areas carefully.

- Flapping: A flapping noise could be caused by a fan blade hitting something. Check your cooling fans for obstructions or damage.

- Grinding: If you hear grinding during braking, it could be worn brake pads or rotors. For rear-wheel models, check the drums and shoes as well.

- Groan: A low groaning sound is often caused by dry suspension components. Apply silicone lubricant to rubber parts or consider replacing metal ones if needed.

- Hiss: A hissing noise usually indicates a leak in the cooling system. If it gets louder when accelerating, it could be a bad belt.

- Hum: A humming sound that changes with acceleration or deceleration might be related to the differential or wheel bearings. Ask a passenger to help determine which side the noise is coming from.

- Knock: A knocking sound can be a sign of serious engine trouble, such as a failing rod bearing or wrist pin. Check oil pressure first, then listen closely at 2,500 RPMs for any changes.

- Ping: A pinging or knocking sound during acceleration is often caused by pre-ignition. This could be due to a clogged EGR valve or advanced ignition timing.

- Pop: A popping sound from the engine could mean a leaking or sticking valve, or a jumped timing chain. Check your distributor, rotor, and position sensor as well.

- Rattle: A rattle might come from loose exhaust hangers or brake calipers. Tighten or replace these parts if necessary.

- Roar: A roaring sound could be a sign of improper transmission shifting or worn tires. Check your tire tread and ensure your transmission is functioning correctly.

- Scraping: A scraping noise might be caused by an object rubbing against the driveshaft. Inspect the undercarriage for any foreign objects or damaged parts.

- Sizzling: Sizzling sounds often occur when fluids like oil or coolant are leaking onto hot engine parts. Check for leaks and repair them immediately.

- Squeal: A squealing noise is commonly linked to the brakes, but it could also be a loose or worn belt. Check your brake pads and rotors, and inspect all belts for wear.

- Tick: A ticking sound usually comes from the valve train. It could be a stuck lifter or excessive clearance between parts. A quick inspection might reveal the cause.

- Whine: A whining noise could indicate a failing bearing, alternator bushing, or low lubrication in the gearbox. Check each component for signs of wear.

- Whistle: A whistling sound is often caused by wind entering through damaged weather stripping. Inspect the seals around your doors and windows.

Remember, every noise your Toyota makes is a clue. Don’t hesitate to take your vehicle to a professional if you're unsure. Regular maintenance and prompt attention to strange sounds can save you time, money, and stress in the long run.

Related Posts

Tower Crane cabin is the control center of the crane and is attached to the slewing unit. In order to get to the tower crane cab, the operator must climb a series of ladders within the mast.

The movement of the tower crane is controlled from the operator's cabin. Within the tower crane cabin, you'll find the operator's chair with joystick controller, electronic monitoring devices, and communication systems. Many cabins come with climate control to ensure a comfortable work environment. The Operator Cabin for Tower Crane is part of the slewing assembly.

A cabin for a tower crane is a small enclosed space located at the top of the tower crane Mast Section or tower crane jib. It is where the crane operator sits and controls the crane's movements and operations. The tower crane cabin is typically made of steel or aluminum and is designed to provide a safe and comfortable working environment for the operator. It is equipped with controls, instruments, and communication systems that allow the operator to maneuver the crane, lift and lower loads, and communicate with other personnel on the construction site. The cabin is often equipped with heating and air conditioning systems to ensure the operator's comfort in various weather conditions. Safety features such as guardrails, harness attachment points, and emergency controls are also included in the cabin design to protect the operator in case of accidents or emergencies.

Tower Crane Cab,Tower Crane Cabin Chair,Tower Crane Operator Cabin, Operator Cabin for Tower Crane,Driver's Cabin for Tower Crane

SHEN YANG BAOQUAN , https://www.bq-cranes.com

Toyota Spark Plug Replacement – 90080-91180

Toyota Spark Plug Replacement – 90080-91180  How To Figure Out Why Your Toyota Is Overheating

How To Figure Out Why Your Toyota Is Overheating  Toyota Mud Guard Replacement – 76622-04102

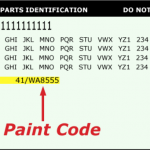

Toyota Mud Guard Replacement – 76622-04102  4th Gen Toyota 4Runner Paint Code Guide

4th Gen Toyota 4Runner Paint Code Guide  5 Tips For Protecting Your Toyota’s Windshield

5 Tips For Protecting Your Toyota’s Windshield  Toyota Won’t Start? Troubleshooting Tips To Get You Back On The Road

Toyota Won’t Start? Troubleshooting Tips To Get You Back On The Road