Structural steel grades are essential construction materials designed for use in building and infrastructure projects. These grades of steel are specifically formulated to offer high strength, durability, and versatility. They consist primarily of iron and carbon, with additional elements that enhance their mechanical properties. Structural steel is typically manufactured into specific cross-sectional shapes such as beams, columns, and plates, making it ideal for a wide range of applications.

Table of contents

- What is Structural Steel?

- Producing & Testing of Structural Steel

- Properties of Grade E250

- Mechanical Properties of SS Grade E250

- Structural material grades Types

- What are The Different Grades of Structural Steel ?

- Structural Steel Standards

- Different Shapes of Structural cold formed steel

- Strength-Weight Ratio of Structural Steel

- Structural Steel vs Stainless Steel

- Yield Strength of Structural cold formed steel

- Tensile Strength of Structural beam

- Chemical Composition of Structural Steels

- E250 material Chemical Composition

- Advantages and Disadvantages of structural galvanized steel

- Benefits of Structural Steel Hollow Sections

- Characteristic of AISI 304 & 316

- S235 Steel Hollow Section Square Weight Chart

- S355 Steel Density kg/m3

- Mechanical Properties of Steel Grade E350

- E350 steel Chemical Composition

- Inspection Checklist of S235 Grade

- Structural Steel and Reinforcement Steel Difference

- Applications of S420 Material

What is Structural Steel?

| Aspect | Details |

|---|---|

| Purpose | Construction material in various shapes |

| Profiles | I-beams, channels, angles, hollow sections |

| Fabrication Methods | – Hot Rolling: Shaping with heat – Cold Rolling: Shaping at room temperature – Welding: Joining sections – Bending: Creating curves |

| Applications | Buildings, bridges, roads, infrastructure projects |

Producing & Testing of Structural Steel

| Aspect | Details |

|---|---|

| Composition | Alloy of iron and carbon |

| Production Methods | – Recycled Steel: Melting and refining – Raw Materials: Extraction from iron ore |

| Iron Extraction | – Process: Grinding taconite, magnetic separation – Iron Ore Characteristics: Raw ore is soft; carbon adds strength |

| Iron-Carbon Alloy Production | – Reduction Process: Heating coke with iron ore to bond carbon with oxygen – Carbon Content: Below 2.1% to form steel; structural steel has 0.05-0.25% carbon |

| Properties of Structural Steel | High strength-to-weight ratio 100% recyclable Cost-effective |

| Grades | Various grades with slight composition differences for specific needs |

Check Structural Steel Grade E250 Properties

Due to its remarkable properties, Grade E250 has become a preferred choice for construction and infrastructure projects. It offers excellent weldability, formability, dimensional accuracy, toughness, and heat treatability, making it ideal for creating sturdy and reliable structures. Below are some key features of this grade:

Properties of Grade E250

- Good weldability

- Good formability

- Good dimensional accuracy

- Toughness

- Heat treatable

- Sturdy construction

Mechanical Properties of SS Grade E250

| Property | Value |

|---|---|

| Yield Strength | 250 N/mm² |

| Tensile Strength | 410 N/mm² |

| Elongation | 23% minimum |

View the Standard Structural Steel Materials and Standards

Structural steel is a versatile and durable material used extensively in the construction industry. Its unique combination of properties makes it suitable for a variety of applications. Engineers carefully select the right type of structural steel based on the specific requirements of each project. This ensures optimal performance and long-term reliability.

The following information provides an in-depth look at different types of structural steel and their characteristics.

Structural material grades Types

| Steel Type | Key Features | Common Uses |

|---|---|---|

| Carbon Steels | No major alloys; Cu ≤ 0.6%, Mn ≤ 1.6%, Si ≤ 0.6% | Structural pipes and tubing |

| High-Strength, Low-Alloy Steels | Mn up to 2%; trace Cr, Ni, Mo, etc. | Structural shapes and plates |

| Forged Steels | Uniform grain structure; enhanced strength | High-strength applications |

| Quenched and Tempered Alloy Steels | Heat and rapid cooling; tough and strong | High-strength structural uses |

What are The Different Grades of Structural Steel ?

| Steel Type | Key Features | Common Uses |

|---|---|---|

| A36 Steel | – Low-carbon & Good weldability – Yield strength: 36,000 PSI |

Construction, bridges |

| A572 Steel | – High-strength low-alloy – Yield strength: 50,000 PSI |

Bridges, offshore platforms |

| A992 Steel | – Higher strength than A36 – Yield strength: 50,000 PSI |

Commercial buildings, bridges |

| A500 Steel | – Yield strength: 46,000 PSI – Tensile strength: 62,000 PSI |

Building frames, columns |

| A514 Steel | – High-strength – Yield strength: 100,000 PSI |

Heavy machinery, mining equipment |

| A516 Steel |

– Yield strength: 38,000 PSI – Tensile strength: 70,000 PSI |

Pressure vessels, boilers |

| A242 Steel | – Low-alloy high-strength – Yield strength: 50,000 PSI |

Outdoor structures, marine applications |

| A588 Steel | – Yield strength: 50,000 PSI – Excellent corrosion resistance |

Bridges, infrastructure |

| A709 Steel | – High-strength low-alloy – Yield strength: 50,000 PSI |

Bridges, buildings |

| A913 Steel | – High-strength low-alloy – Yield strength: 50,000 PSI |

Bridges, buildings |

Structural Steel Standards

ASTM Standards of Structural Steel

- ASTM A36

- ASTM A500

- ASTM A572

- ASTM A588

- ASTM A709

- ASTM A992

- ASTM A285

- ASTM A514

- ASTM A516

European (EN) Standards of Structural Steel

- S235JR – EN 1.0038

- S275J2 – EN 1.0145

- S355JR – EN 1.0045

- S235J2 – EN 1.0117

- S275JR – EN 1.0044

- S355J0 – EN 1.0553

- S420M – EN 1.8827

- S355J2 – EN 1.0577

US Standards of Structural Steel

- A283C

- A570Gr40

- A572Gr50

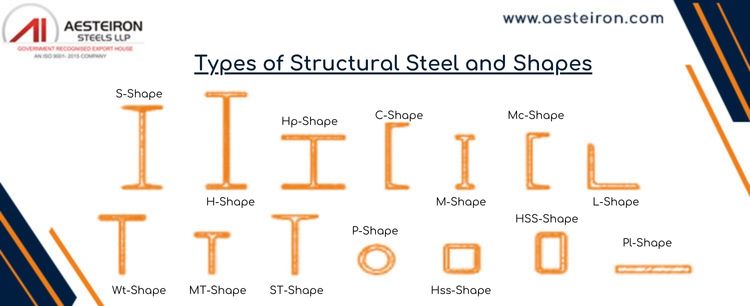

Different Shapes of Structural cold formed steel

| Shape | Description | Common Uses |

|---|---|---|

| L-Shape | Corner section; resembles the letter "L" | Construction, industry, mining |

| U-Shape | Two parallel sides; resembles the letter "U" | High durability applications |

| C-Shape | Cross-section resembles the letter "C" | Purlins below roofs |

| Z-Shape | Cross-section resembles the letter "Z" | Purlins, similar uses to C-shape |

| Tubular Hollow Cross-Section | Tubular with hollow cross-section | Multi-axis constructions |

| Flatform | Plates used for attachment | Enhances bearing strength in construction |

| Rectangular Hollow Cross-Section | Rectangular open cross-section | Mechanical and construction industries |

| Square Hollow Cross-Section | Square open cross-section | Columns or pillars |

| Taper-Shaped Beams and Columns | Tapered shape | Industrial prefabricated steel buildings |

S235 Steel Are Designed to Have Good Strength / Weight Ratio

This structural steel grade is known for offering a good balance between strength and weight. With a yield strength of 235MPa, it can withstand significant loads without permanent deformation. Its favorable strength-to-weight ratio makes it ideal for applications where reducing weight is crucial while maintaining structural integrity and durability.

Strength-Weight Ratio of Structural Steel

| Aspect | Description |

|---|---|

| Strength-to-Weight Ratio | Strength divided by density; indicates material efficiency. |

| Purpose | Categorizes materials based on their suitability for specific uses. |

| Example: Concrete | – High compression strength-to-weight ratio. – Less effective in tension strength. – Ideal for compression-focused applications. |

| Usage | Helps determine material suitability for various structural needs. |

Structural Steel vs Stainless Steel

| Aspect | Structural Steel | Stainless Steel |

|---|---|---|

| Materials | Iron + <1.5% carbon | Iron + Chromium, sometimes Nickel, Titanium |

| Common Uses | Beams in high rises, structural applications | Cutlery, medical materials, decorative plates |

| Strength & Hardness | Higher iron content; very hard | Slightly weaker; more malleable at room temperature |

| Ductility | Less ductile compared to stainless steel | Higher ductility due to added nickel |

| Cost | Less expensive | More expensive due to alloying elements and production |

| Magnetism | Generally magnetic | Typically non-magnetic; some grades may be magnetic |

| Temperature | Higher melting point | Lower melting point, but overlap with structural steel |

Yield Strength of Structural cold formed steel

|

Grade |

Minimum Yield Strength |

|

|---|---|---|

| N/mm2 (MPa) | PSI | |

| S235 | 235 N/mm2 | 33 000 |

| S275 | 275 N/mm2 | 36 000 |

| S355 | 355 N/mm2 | 50 000 |

Tensile Strength of Structural beam

| Grade | Tensile Strength MPa |

|---|---|

| S235 | 360 – 510 MPa |

| S275 | 370 – 530 MPa |

| S355 | 470 – 630 MPa |

Chemical Composition of Structural Steels

| EU Grade | Mn% | C% | Si% | S% | P% |

|---|---|---|---|---|---|

| S235 | 1.60 max | 0.22 max | 0.05 max | 0.05 max | 0.05 max |

| S275 | 1.60 max | 0.25 max | 0.05 max | 0.05 max | 0.04 max |

| S355 | 1.60 max | 0.23 max | 0.05 max | 0.05 max | 0.05 max |

Structural Steel Grade E350 Have a Carbon Content Between 0.1 and 0.3%

E250 material Chemical Composition

| Grade | C | S | Mn | P | Si | Carbon Equivalent (CE), Max |

|---|---|---|---|---|---|---|

| IS 2062 E350 | 0.20 | 0.045 | 1.50 | 0.045 | 0.45 | 0.42 |

S420 Steel Material is Very Durable and is Resistant to Mold, Moisture

This grade of structural steel is known for its durability and resistance to moisture conditions. Due to its chemical composition, it provides protection against environmental factors that could affect its shape and performance over time. This makes it highly applicable for long-term construction applications where longevity is critical.

Advantages and Disadvantages of structural galvanized steel

| Advantags | Disadvantages |

|---|---|

| Higher strength/weight ratio | Susceptible to corrosion |

| High durability | High fire resistance cost |

| Versatility due to good ductility | high maintenance costs |

| Sustainability | Buckling is an issue |

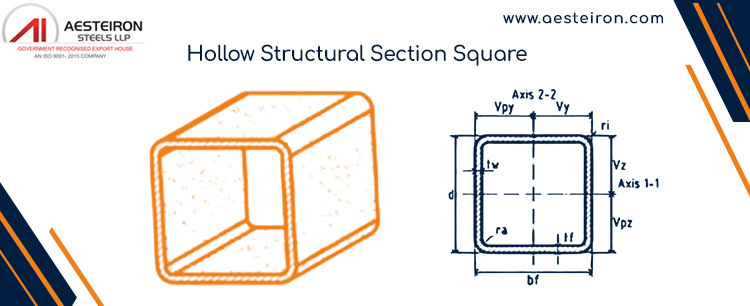

Benefits of Structural Steel Hollow Sections

| Aspect | Details |

|---|---|

| High Strength-to-Weight Ratio | – Economical due to structural efficiencies. – High radii of gyration enhance compression performance and reduce weight. |

| Aesthetic Appeal | – Favored for architectural use. – Smooth sides, rounded corners, and closed sections are ideal for exposed structures. |

| Less Surface Area for Coatings | – Rectangular and square HSS have ~2/3 the surface area of open sections with similar capacity. – Reduces surface preparation, painting material, labor, and fireproofing. |

| Closed Section | – Effective at resisting torsional loads. – Minimal surfaces collect dust and debris, suitable for clean environments. |

Characteristic of AISI 304 & 316

| Characteristics | 304 stainless steel | 316 stainless steel |

|---|---|---|

| Weldability | High | Good |

| Corrosion resistance | Excellent | Even better |

| Magnetic | No | No |

| Hardens during cold forming | Yes | Yes |

| Machinability (annealed) | Fair, but better than 316 | Fair |

| Resists elevated temperatures | High | High |

| Formability | Very good | Good |

| Maximum intermittent service temperature | 1562°F | 1562°F |

S235 Steel Hollow Section Square Weight Chart

| Section Index | Weight | Area | Sizes | Corner Radius | Axis 1-1 | Axis 2-2 | ||||||||||

| Depth | Width | Thickness | ra | ri | Ix | Sx | rx | ly | Sy | ry | Vpy | Vpz | ||||

| Ax | d | bf | tf | tw | ||||||||||||

| (lb/ft) | (in2) | (in) | (in) | (in) | (in) | (in) | (in) | (in 4) | (in2) | (in) | (in 4) | (in2) | (in) | (in) | (in) | (in) |

| HSSQ22x22x0,875 | 244 7/8 | 67 2/7 | 22 | 22 | 4/5 | 4/5 | 4/5 | 1 5/8 | 4970 | 530 | 8 3/5 | 4970 | 530 | 8 3/5 | 11 | 11 |

| HSSQ20x20x0,75 | 4/7 191 | 52 3/5 | 20 | 20 | 2/3 | 2/3 | 2/3 | 1 2/5 | 3230 | 378 | 7 5/6 | 3230 | 378 | 7 5/6 | 10 | 10 |

| HSSQ22x22x0,75 | 212 | 58 1/5 | 22 | 22 | 2/3 | 2/3 | 2/3 | 1 2/5 | 4350 | 462 | 8 2/3 | 4350 | 462 | 8 2/3 | 11 | 11 |

| HSSQ20x20x0,875 | 221 | 60 4/5 | 20 | 20 | 4/5 | 4/5 | 4/5 | 1 5/8 | 3670 | 433 | 7 7/9 | 3670 | 433 | 7 7/9 | 10 | 10 |

| HSSQ20x20x0,625 | 161 2/5 | 44 2/7 | 20 | 20 | 4/7 | 4/7 | 4/7 | 1 1/6 | 2750 | 320 | 7 7/8 | 2750 | 320 | 7 7/8 | 10 | 10 |

| HSSQ20x20x0,5 | 130 1/2 | 35 4/5 | 20 | 20 | 1/2 | 1/2 | 1/2 | 1 | 2260 | 261 | 8 | 2260 | 261 | 8 | 10 | 10 |

S355 Steel Density kg/m3

| Material Property | Value |

|---|---|

| Density Ï | ≈ 7850 kg/m3 |

| Unit weight γ | ≈ 78.5 kN/m3 |

| Modulus of elasticity E (Young’s modulus) |

210000 MPa |

| Shear modulus G | G = E / [2 ⋅ (1 + ν) ] ≈ 81000 MPa |

| Poisson’s ratio in elastic range ν | 0.30 |

| Coefficient of linear thermal expansion α | 12 ×10-6 °K-1 |

Mechanical Properties of Steel Grade E350

| Tensile Strength in Mpa | 490 min. |

|---|---|

| Yield Strength in Mpa | 320 min. |

| Hardness in BHN | 170 – 207 |

| Elongation in % | 22 min. |

| Reduction of Area in % | – |

| Impact in Joule | – |

E350 steel Chemical Composition

| Carbon | C % | 0.200 max. |

|---|---|---|

| Phosphorus | P % | 0.045 max. |

| Silicon | Si % | 0.450 max. |

| Manganese | Mn % | 1.550 max. |

| Sulphur | S % | 0.045 max. |

| Iron | Fe % | Balance |

Inspection Checklist of S235 Grade

- Design code

- Purchase order specification

- Steel Structure Manufacture Quality Control Plan

- Steel Structure Inspection and test plan

- Steel Structure Data Sheet

- Steel Structure Approved Drawings

- Steel Structure Strength calculation sheets

- Steel Structure Material Test Reports

- Certificate No.

- Heat or cast No.

- Chemical composition.

- Mechanical properties.

- Heat treated condition.

- NDE applied and results.

- Welders properly qualified

- Test coupons compiled where necessary

- Dimensional check on pre-drilled parts

- Correct fastening being used

- Protection of protruding parts

- Shipping and other marks

Structural Steel and Reinforcement Steel Difference

| Aspect | Structural Steel | Reinforced Steel |

|---|---|---|

| Primary Use | Forming the frames of buildings and structures | Reinforcing concrete and masonry structures |

| Materials | Various types of steel, including carbon-manganese, high-strength low-alloy | Hot rolled deformed bars, mild steel plain bars, cold worked steel reinforcements |

| Forms | Beams, braces, plates, columns in various shapes (S, L, H, C, I, HSS, T, Pipe) | Steel bars (rebar) in various forms and treatments (hot rolled, cold worked, etc.) |

| Shapes | Defined by cross-sectional shapes such as S, L, H, C, I, HSS, T, Pipe | Typically round or square bars, not defined by cross-sectional shapes |

| Key Characteristics | High strength, flexibility | |

| Typical Applications | Used in constructing beams, columns, bridges | |

| Strength Focus | Focuses on overall structural strength and load-bearing capacity | |

| Compatibility | Can be used alone or with concrete and wood |