# Modern Industry and the UT Drone

In every corner of the globe, industries follow their own specific rules and regulations to ensure safety for people, the environment, and equipment. These guidelines are set by a variety of organizations ranging from government bodies and national agencies to international class societies and multinational entities.

A successful inspection relies on reliable data, yet gathering this information isn't always straightforward. For instance, inspecting assets like ships or storage tanks can pose challenges when trying to collect data safely. As a result, alternative methods of access are gaining traction and popularity, with drones being a significant part of this shift. These unmanned systems can access hard-to-reach areas at heights, in confined spaces, or even underground to gather crucial data necessary for inspections but otherwise unreachable. Enter the **UT drone**.

## What Is a UT Drone?

A **UT drone** is an unmanned aerial vehicle (UAV) equipped to perform ultrasonic thickness measurements. This technology allows for gathering ultrasonic thickness (UT) data from places that are difficult or dangerous for inspectors to reach, such as chimneys, ballast tanks, or flue ducts.

A **UT drone** plays a key role in **drone-enabled non-destructive testing**, streamlining inspection processes. By providing safer access to assets, drones enhance inspection efficiency and improve overall asset management.

*Caption: Every industry adheres to stringent safety protocols. In sectors like shipping, ultrasonic testing equipment is vital for assessing asset conditions.*

## How Does a UT Drone Work?

Traditional ultrasonic testing involves placing an ultrasonic probe against the test surface and transmitting sound waves through the material. The reflection of these waves is analyzed by the probe to determine the material's thickness.

However, many standard drones aren't designed to handle contact with surfaces or maintain stable hovering for extended periods, making ultrasonic testing challenging. This is why **UT drones** are highly specialized, engineered to function in diverse environments beyond what typical drones can achieve.

*Caption: A UT drone carries a specialized payload equipped with an ultrasonic thickness measurement probe.*

**UT drones** approach a measurement point, position their probe against the surface, apply couplant to ensure optimal sound transmission, and then take the measurement. Some models allow pilots to adjust gain and gates based on the material being tested. Once the measurement is complete, the drone detaches and moves to another location.

### How Many Measurements Can a UT Drone Take?

The number of measurements a **UT drone** can perform depends on its flight time, the amount of couplant it can carry, and the pilot's skill. For example, the Elios 3 UT drone can complete up to 40 UT measurements per flight.

## Benefits of a UT Drone

As part of drone-enabled non-destructive testing, a **UT drone** brings numerous advantages to inspections, enhancing safety, efficiency, and accessibility while reducing overall costs.

### SAFETY

Using a **UT drone** minimizes human exposure to inspection-related risks. Measurement points at heights or in confined spaces often require special permits and safety protocols. Finding certified UT inspectors who are also trained in rope access is challenging, increasing demand for skilled personnel.

Alternatively, **UT drones** can navigate confined spaces as small as 50x50 cm (20x20 inches), collecting dozens of measurements per flight. This reduces exposure to risks like toxic gases, asphyxiation, and drowning. Similarly, **UT drones** can access high-risk areas like inside chimneys or ship hulls, eliminating the need for scaffolding or rope access. For flue duct inspections, regulations may require exits at both ends for human entry, necessitating duct modifications. A **UT drone**, however, can enter and exit without human intervention, minimizing downtime.

*Caption: A UT drone can inspect confined spaces like this tank without endangering human lives.*

### EFFICIENCY

A **UT drone** inspection can be completed in under an hour. Deployment takes mere minutes, and pilots can guide the drone beyond the line of sight using its high-definition camera. Some **UT drones** even offer real-time LiDAR scans for 3D mapping.

Drones can swiftly transition between measurement points, regardless of distance, far faster than moving scaffolding or adjusting rope access technicians. They also surpass mobile elevated work platforms (MEWPs) in terms of speed and flexibility, navigating both indoors and outdoors without height or breadth restrictions.

The efficiency of **UT drone** inspections is further enhanced by the recording process. Previously, UT measurements were shouted down to someone on the ground, leading to potential inaccuracies and unclear location identification. Chalk markings on assets were similarly unreliable and prone to fading. In contrast, a **UT drone** tags each measurement point's location, enabling precise identification of areas requiring maintenance. When combined with 3D scans, a digital asset record is automatically generated, simplifying updates and tracking changes over time.

*Caption: Here are ultrasonic thickness measurements geotagged by a UT drone during flight.*

This streamlined asset management process extends the lifespan of assets through improved oversight.

### ACCESS

A **UT drone** can access locations unreachable by conventional methods, whether confined spaces, inside stacks, or even machinery. Some **UT drones** can operate in GPS-denied environments, unlocking access to underground or confined spaces effortlessly.

Enhanced access and ultrasonic testing capabilities with **UT drones** enable more frequent inspections. For instance, measuring at heights where scaffolding would take over a day to install or dismantle can now be done in minutes. More frequent inspections allow for early problem detection and better asset condition monitoring. **UT drones** promote optimal asset management by facilitating critical data collection without extended downtime or higher costs.

*Caption: A UT drone can explore complex environments and gather previously inaccessible data.*

## UT Drone Case Studies

### Saving 15,000 Hours on a Ship Hull Inspection

The Elios 3 UT was utilized for periodic cargo oil tank inspections on a medium-sized ship. Typically, such inspections required scaffolding and a team of over 16 people. Using the Elios 3, all measurements were gathered efficiently with the UT drone.

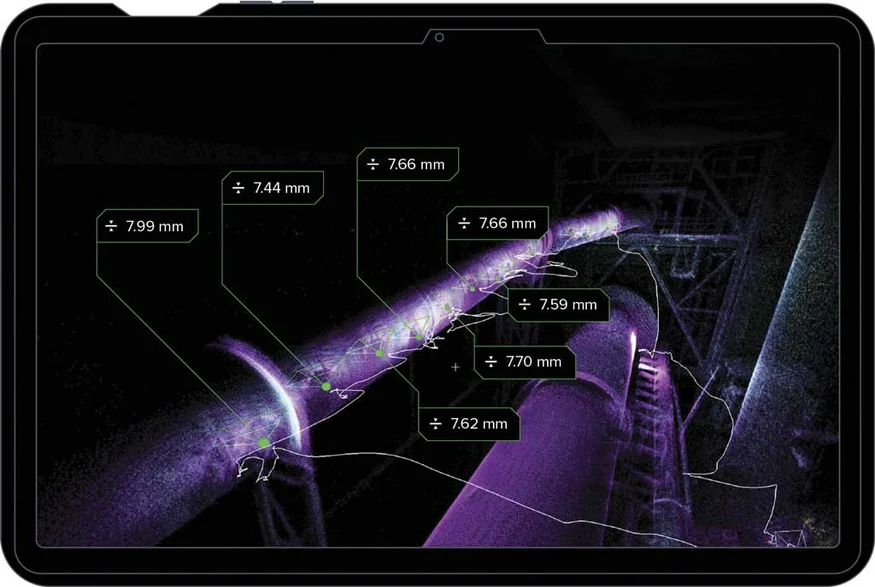

*An example point cloud with the Elios 3 UT payload showing spot measurements located in the point cloud.*

Discover the UT drone for ship surveys [here](#).

### Stack Inspection with a Drone

A stack at a power generation facility needed inspection. Exterior insulation complicated access, and harsh Canadian weather added further challenges. The Elios 3 UT drone offered an ideal solution, flying inside the stack without insulation to gather measurements, eliminating the need for insulation removal or scaffolding.

*Thanks to the Elios 3's camera, UT inspections can be conducted beyond the visual line of sight. The Cockpit app also allows manual adjustments to gain and gates, as shown here.*

Read the full UT stack inspection case study [here](#).

### Flue Duct and Silo UT Measurements

At a German cement plant, an inspection team explored the viability of using a UT drone. They found the Elios 3 UT could inspect standard assets like flue ducts and silos without scaffolding or disruptions, providing easy access to previously unreachable areas.

*The Elios 3 and its UT payload navigated bends and dust-filled flue ducts with ease.*

Discover the Elios 3 UT for cement plant inspections [here](#).

---

With the advent of **UT drones**, the future of industrial inspections is brighter, safer, and more efficient than ever before.

The PE Pipe Production Line can be categorized based on the pipe diameter and application.

1. PE Water Supply Pipe Production Line

This production line can produce pipes with a diameter range of 16mm to 1200mm. For example, the XDC-HDPE63 model can produce pipes with a diameter of 16-63mm, with a maximum output of 200 kg/h.

It is designed for high-speed production and features a stable and simple operation. The pipes produced have smooth inner walls, extremely low friction coefficients, good flexibility, high impact strength, and corrosion resistance.

Widely used in municipal water supply systems, building water supply systems, and industrial water treatment systems.

2. PE Gas Pipe Production Line

Similar to the water supply pipe production line, it can produce pipes with a diameter range of 16mm to 1200mm. The XDC-HDPE160 model, for instance, can produce pipes with a diameter of 63-160mm, with a maximum output of 300 kg/h.

The production line is equipped with advanced extruders and precision die heads to ensure the quality of the pipes. The pipes have good flexibility, high impact strength, and corrosion resistance.

Used for gas transportation piping systems in various industries.

3. PE Communication Pipe Production Line

This production line is designed to produce pipes with a diameter range of 16mm to 1200mm. The WR-630 model can produce pipes with a diameter of 250-630mm, with a maximum output of 1100-1200 kg/h.

It features a high degree of automation and optimized screw structure, ensuring stable production efficiency. The pipes produced have excellent corrosion resistance, compression resistance, and impact resistance.

Suitable for power communication systems.

4. PE Silicone Core Pipe Production Line

This production line can produce pipes with a diameter range of 16mm to 1200mm. The pipes have a silicone solid lubricant on the inner wall.

The silicone core pipe is widely used in optical cable communication network systems for railways and highways. It has the advantages of being moisture-proof, insect-proof, anti-corrosion, and anti-aging.

Used in optical cable communication network systems.

PE Pipe Extruder,Plastic Pipe Extruder,Plastic Pipe Extrusion Machine,PP Plastic Extruder,PE Pipe Extruded,PP Pipe Extruded

Zhangjiagang Polestar Machinery Co.,Ltd , https://www.polestarpm.com